I will show you how easy it is to cut a thread on a water pipe for an ordinary home craftsman, without any skills in this matter and with a minimal set of tools. For example, when replacing a central heating battery, as in my case. There is absolutely nothing complicated about this and the method is accessible to almost everyone. So, you cut the pipe with a grinder or other tool, such as a hacksaw. The main thing is that the cut is even and perpendicular.

Features of the technology

When cutting internal threads with a tap, the following algorithm is used.

- In the place on the surface of the workpiece where the hole for threading will be drilled, it is necessary to form a recess for a more accurate entry of the drill, using a core and a regular hammer. The drill is fixed in the chuck of an electric drill or drilling machine, on which low rotation speeds of the tool are set. Before starting drilling, the cutting part of the drill must be treated with a lubricating compound: a lubricated tool enters more easily into the structure of the material being processed and creates less friction in the processing area. You can lubricate the drill with a piece of ordinary lard or grease, and when processing viscous materials, machine oil is used for these purposes.

- If it is necessary to cut threads in small parts, they should first be fixed using a bench vice. When starting drilling, the tool fixed in the equipment chuck must be positioned strictly perpendicular to the surface of the workpiece. You should lubricate the tap regularly and ensure that it does not warp and moves strictly in the given direction.

- At the entrance to the hole, as mentioned above, it is necessary to remove the chamfer, the depth of which should be 0.5–1 mm (depending on the diameter of the hole). For this purpose, you can use a larger diameter drill or countersink, installing them in the chuck of drilling equipment.

- The process of cutting internal threads begins with tap No. 1, which is the first to be installed in the driver. We should not forget about the lubricant, which must be applied to the tap for threading. The position of the tap relative to the hole being machined must be set at the very beginning of the work, since later, when the tool is already inside the hole, this will not be possible. When cutting a thread with a tap, you must adhere to the following rule: 2 turns of the tap are made in the direction of cutting the thread, 1 - against the direction. When the tap makes one revolution back, chips are thrown off its cutting part and the load on it is reduced. Thread cutting with a die is performed using a similar technique.

- After cutting the thread with tap No. 1, tool No. 2 is installed in the driver, and after it – No. 3. They are processed according to the method described above. When cutting threads with taps and dies, you need to feel when the tool begins to rotate with force. As soon as such a moment occurs, you should turn the knob in the opposite direction to throw the chips off the cutting part of the tool.

The harder the material being processed, the more abundantly the tap must be lubricated during the thread cutting process.

Before making internal threads with a tap or cutting threads with a die on external surfaces, you should thoroughly study these procedures and strictly follow the rules for their implementation. Only in this case can you count on the result satisfying you with its quality and accuracy.

Tapping internal threads

Using a tap, cut the internal thread in the pre-drilled hole. The hole should be smaller by approximately the thread size (the thread size is indicated on the tap). Approximately as in the table:

Hole diameter for internal thread with tap

It is worth remembering that the drill will not give an absolutely accurate diameter; it will be larger by a few fractions of a mm. This is especially noticeable on diameters up to 3 mm. This should be taken into account and take a drill less than a tenth of a mm.

Just like with dies, there is a tap holder.

There are rough and finishing taps. Sometimes they cut first with a rough tap, then with a finishing tap, but mostly they use finishing taps straight away.

Manual cutting of internal threads with a tap (video)

The process is almost identical to thread cutting with a die. The tap is attached to the holder and installed perpendicular to the hole. The part with the hole must be securely fastened.

The tap and hole are lubricated and this is done periodically, after several turns. Just like with a die, you need to make 1-2 turns and 0.5 turns back to remove chips.

To check the accuracy of thread cutting, use a square, checking the verticality of the tap after several turns.

Plumbing Repair Basics

Not many people have thought about how to connect the water supply to a private house.

It consists of:

- pipes,

- valves,

- valves

- taps and other components.

All this is assembled into a single system using threaded connections.

To ensure that the process of replacing an old part with a new one does not take much time, there is a thread.

Sometimes you have to deal with cases when you yourself have to change a worn-out element (for example, a pipe), but there are no grooves on it.

What to do in this case?

The way out of this situation is very simple - cut the thread with your own hands. The ideal option is when you have the opportunity to use a lathe.

But not every home craftsman has such equipment.

It is expensive, and in order to use it you need to have certain experience and skills.

If you need to equip a pipe with threads, for example, to connect a membrane tank for water supply (written here), you can use one of two types of devices designed for cutting grooves:

- thread-cutting tray,

- pipe wrench

This tool is used to cut threads in water and sewer pipes (read why a water seal is needed here), which are used in the utility networks of multi-storey buildings and private buildings.

Note! If you do not have any experience in this matter, then working with a lecher will be very difficult for you. Since even the slightest misalignment of the tool will invariably lead to the formation of a defect

In this case, it is best to use a wrench; the cutting process with its help is simplified by the presence in the design of such an important part as a guide. In order not to spoil the water pipe, to acquire a certain skill, practice on an unnecessary piece of a hollow object

In order not to spoil the water pipe, to acquire a certain skill, practice on an unnecessary piece of a hollow object.

Now let's try to refresh our memory about what the thread cutting process is:

- when grooves are applied to pipes, a helical surface is formed on the outside of the hollow object;

- the helical plane plays the role of a connecting element, which rotates steadily around the axis of the fitting;

- The thread pitch corresponds to one full turn.

In order for the junction of water pipes to be waterproof, durable, and the unit to withstand high pressure in the system, it is necessary to cut the threads so that the pitch exactly matches the pitch of the joining parts.

Video description

This video shows how to cut an internal thread using a machine and a tap:

Cutting with an electric die is similar to the conventional process, but this tool requires more space and additional fixation to operate. Its advantage is that the labor intensity of the process for the mechanic is reduced. For any type of cutting, it is recommended to add lubricant during operation to the places where the cutting edge is located.

Thread cutting can also be done using a lathe. This type of work is most often used for large volumes of production. Using such a device, you can make both external and internal threads, but you need a trained specialist to work with them. Without proper knowledge, operating the machine can cause injury.

Example of plumbing fittings with threadSource static-eu.insales.ru

Purpose

The tool allows you to cut cylindrical or conical threads. The working area consists of edges that are made like grooves; they cut the required number of threaded turns. A die consisting of a conical cutting edge and a calibrating edge is suitable for cutting cylindrical threads. For the production of tools, two types of material are used:

- Р18 and Р9 – high-speed steel;

- KhVSG, 9ХС – alloyed instrumental.

It is important to note that the production of dies is regulated by GOST. If the task is a round thread, use a product that performs cutting in accordance with GOST 13536-68, conical - 6211-81, metric - 9150-81, inch - 6111-52, cylindrical - 9740-71

What is a klupp?

Pipe clamps can be compared to dies. They are a monolithic tooling that allows you to cut precise grooves on metal of the desired shape. However, the solidity of the structure creates serious stress when processing large-diameter pipeline elements. You can relieve stress by making the die body less durable. But this will reduce the hardness of the incisors, causing them to quickly become dull. To extend the service life of the blade before sharpening, the equipment is equipped with a spring mechanism.

The klupp is not much different from the die familiar to plumbers. It consists of a cylindrical body made of metal with holes for removing chips. There are separate clamps around the perimeter of the metal ring to securely hold the equipment on the pipe. The incisors arranged in a certain order are fixed on the inside.

Types of clumps

In the technical literature and among manufacturers, there is no unified classification of screws for thread cutting, as well as the need for it. Suitable tools for different types and volumes of work, as well as for different types of pipe material, can be selected at any specialized tool store.

The selection parameters are the pipe diameter and the purpose of the connection, which determine the type and diameter of the thread. The choice of manual or electric execution of the clamp depends on the volume of work, its one-time, periodic or professional nature.

This quality can also be affected by the availability of power supply at the work site.

Manual

A hand-held pipe thread clamp is a common tool for plumbers and plumbers. They can be used to cut a new thread or drive an existing thread when installing or repairing a pipeline in an apartment or in a country house, basement or well. Unlike a classic die, a die allows you to do this work in inconvenient and hard-to-reach places.

The disadvantage of a manual clamp can be considered the rather large forces on the handles.

The standard ½ and ¾ inch threads for residential and public utility pipelines can be handled without any special skills; with larger diameters, cutting time can take significantly and disproportionately more.

Accordingly, the length of the lever of the handle or ratchet increases with the force, so with diameters above one or one and a half inches, hand clamps are practically not used.

An electric socket is a professional tool; purchasing it for home work is unprofitable and impractical.

The electrical output of these machines ranges from 800 to 1700 tons, and they are typically offered with a set of interchangeable die heads for pipe diameters ranging from 15 to 50 mm for metric threads, or 1/1 to 2 inches for pipe threads.

The number of heads in a set can range from 3 to 6 depending on the diameter and material of the pipe. Using such a device is much more convenient and faster than using a manual one.

Just like for any other tool, when choosing a die, you should be guided by the golden rule of the optimal price-quality ratio for the user.

As experience and reviews from experienced craftsmen show, for metal-cutting tools in general, for thread-cutting tools and for die-cutting tools in particular, quality implies an appropriate price, and the price of a product mainly corresponds to its quality.

As already noted, the most popular among hand-held ones are ½- and ¾-inch diameter dies. Their price range is up to 1000 rubles, which is quite affordable for most potential buyers.

When choosing, it is recommended to focus on the upper limit of the available models. The cast iron body of the clamp is considered undesirable, as it often cannot withstand the forces applied to it.

The cost of an electrified tool is an order of magnitude higher than a manual one, and the price range is much wider. Here, a lot depends on the power and configuration of the set, as well as on the name of the manufacturer.

The number of brands, although smaller than that of manual ones, can still be measured in dozens.

In this case, it is worth paying attention to existing warranties, the availability of service centers, and the availability of spare parts and replacement accessories.

Clamp manufacturers and popular models

The technology for manufacturing thread-cutting tools has long been mastered and is accessible both technically and in terms of cost. This determines a huge variety of manufacturers and brands that offer buyers of all categories manual and electric clamps, for pipe and metric threads.

Serious and powerful brands offer products on their own Internet resources or on specialized websites. Such brands include FIT, VOLL, VIRAX, REKON, domestic ZUBR and ENKOR.

At the market, in a department store or chain supermarket, you can find an instrument with any name, including copied, similar and consonant with any of the above and similar ones. You definitely can’t turn away from such a product either; the nondescript packaging may contain very high-quality content.

Rules for using the tool

Both manual and electric models of the clamp are quite easy to use. At the same time, there is a small but mandatory set of rules for the performer of the work, ensuring the quality of the thread, the convenience of the worker and the safety of the tool.

When cutting threads with a die, significant torque and bending moments act on the pipe, so the tool must be securely fastened to the pipe through a guide; additional fastening may be necessary for the pipe itself.

The quality of the thread largely depends on the correct entry of the cutters, for which a lead-in chamfer must be made at the end of the pipe - depending on the diameter and thickness of the pipe wall using a file, grinder, chamfer cutter or rolling with a hammer.

The clamp, like other metal-cutting tools, should be used with a lubricant and cooling fluid. It will be much easier to cut threads with a die using waste oil, grease or cleaning fluid.

How to cut a thread on a pipe with your own hands: make the thread

Very often, during the installation of pipelines or during its repair, it is necessary to replace old pipes with new ones. To do this, new pipes must be cut with suitable threads.

An experienced craftsman is unlikely to have any problems with all this, because over the years of work he has “taught his hand” and can do everything almost effortlessly. Moreover, professionals have all the necessary tools for this.

What if it is needed by an ordinary person who does not know how to carve a pipe? Plumber services are often prohibitively expensive.

Thread is needed everywhere

So, first you need to remember that pipe threads are always cut. In addition, you don’t have to think long about the sizes, because in all apartments the pipes are standard, and their sizes can be 1″, 1 1/4″, 3/4″ or 1/2″. Therefore, to cut threads with your own hands, you need to acquire a die or pipe clamp.

How to cut a thread on a pipe using a die

First we will talk about the die. Sometimes you can hear this instrument called a “lerka,” although the latter term dates back to the times of the USSR. This is a fairly common tool that can be purchased at any metal-cutting tool store.

But before you go and buy yourself a die, you should find out the size of the pipes on which the thread will be cut. Basically it is half an inch, three quarters or an inch. When the size is known, a regular die with a cylindrical pipe thread is purchased. On such tools, the markings have the letter G, that is, a half-inch die will be marked G1/2″. With the use of such tools, pipe threads will be made correctly.

Since holding a die in your hands, you cannot screw the thread, you need to get a die holder. Its cost may be equal to the cost of the die, or may even exceed it. If the work will be done only once, then you can purchase a Chinese die holder, the price of which is lower than the cost of a domestic one. If you want to buy a quality instrument, then it is better to pay more money, but become the owner of a domestic holder. The reason for the low reliability of the Chinese die is the raw material silumin.

Thread cutting die

How to cut a thread on a pipe with a die is a rather complicated process. At least for those who have never done this before. The whole point is that the die does not have a guide, so it is very difficult to cut the thread evenly right away, and it constantly “bumps”, which should not be allowed. That is why, if you have no experience in cutting threads, then it is better to stock up on a special tool called a die.

Threading a pipe using a screw

Now about how to cut threads on a pipe with a clamp.

This tool is very convenient. Moreover, even a person who has never done anything like this in his life can do everything correctly.

Everything is very easy, and the reason for the ease is the special guide that the tool has. A pipe is inserted into this guide, after which the person only has to twist the die, and the thread will be cut independently almost without effort.

To make the process easier, you can purchase a special ratchet that will allow you to twist the clamp without removing the tool, even if there is little space for this.

If you need to cut threads on a pipe of large diameter, that is, from one inch, then it is better to get a special extension for the ratchet. This will make the lever larger, which means less effort for cutting. Among other things, when cutting threads on pipes manually, you need to water the pipe with a special thread cutting fluid or ordinary machine oil.

This step will make the process easier. Moreover, this technique can be used when cutting threads in any material and with any tool, be it a tap, a die or a die. As you can see, cutting threads with a die greatly simplifies the process of creating threads, but in turn, this leads to increased costs.

Electric machines make work easier

There are also special electrical clamps where cutting threads on a pipe does not require any additional effort.

The principle of operation of such a tool completely coincides with the principle of a manual clamp, but instead of the effort exerted by a person, an electric motor works here. Thus, thread cutting will not be difficult for a person at all, since all he will need to do is install the device on the pipe, having previously lubricated it with oil, and turn on the power plug.

phoenix-master.com

Existing threading options

Pipe threads are divided into five types, but the most popular options are conical and cylindrical. Household members often encounter such types of pipe threads. There are two methods for threading a water pipe:

- Automatic, which involves cutting threads on water supply pipes using special machines and power tools.

- Manual. For this, special hand tools are used.

If, as part of his job, a person needs to cut threads on a large number of pipes, then it is appropriate to purchase a special power tool, which will facilitate manual labor.

When the need to obtain a threaded connection is an isolated case, then manual technology is suitable for such purposes. On water pipelines, as well as pipes of heating systems, thread cutting is performed using a die.

A die (another name for a die) is the simplest device intended for cutting external threaded connections on pipes.

The die is a steel disk, and its inner diameter has axial holes in different numbers, which depends on the size of the product. The edges of these holes form cutters, with the help of which thread cutting is performed. To ensure the reliability of such a tool, it is made of alloy steel or hard alloys.

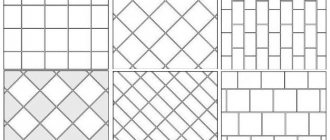

Dies can have different shapes (round, square, hexagonal or prismatic), but most often disc options are used. Disc dies are intended for making threaded connections on water pipes. To make it convenient to work with the die, they are equipped with additional knobs, as well as clamps in the form of screws. Dies are also solid, split and sliding.

What is a thread and why is it needed?

Threading is one of the most popular types of fastening parts or mounting structures. It is used to connect several parts, such as pipes, into one structure. To do this, grooves are cut out on their side or inner part, which have a certain shape, angle of inclination and distance between the recesses (turn pitch).

Also, the notch can be on connecting parts, for example, taps or tees. Using this installation method, you can make collapsible or permanent structures, such as water supply, sewerage and other types of pipe systems. You can cut threads only on round or conical parts, since for other surfaces it will be inconvenient and impractical.

The most common thread profile option is triangular. It is very simple and affordable, but is not suitable for frequent system disassembly. If you need to frequently disconnect pipes or other parts, a round profile is used. It is most often used in plumbing. Other types of profiles are used in kinematic systems (for example, transmissions), but are not used in plumbing.

A type of kinematic cuttingSource findpatent.ru

Briefly about the main thing

Threading is a convenient and reliable way to fasten parts and mount various structures.

There are different types of threads, but for pipes the most commonly used standard is cylindrical or tapered.

The simplest and most accessible tool for cutting external threads is a die, and for internal threads, a tap.

With the help of a die, you can save time and effort when cutting threads in hard-to-reach places, for example, near walls, and the electric device can make the notch independently.

How to cut external threads. Thread cutting on pipes and fittings. Die. Klupp

How to cut external threads. Thread cutting on pipes and fittings. Die. Klupp. 4.46/5 (89.23%) lost 13

External threads are cut using round or sliding dies, as well as screw boards. Thread cutting can be done either on machines or manually.

Cutting threads with round dies.

Round dies (lerks) are a disk with a cut hole. To remove chips and form feathers with cutting edges (Fig. 1), several chip holes are made in the die. The dies (lerks) are inserted into the lerk holder and clamped with screws (Fig. 2).

Rice. 1. Round split die (cutting die).

Rice. 2. Card holder:

1 - frame; 2 - handle; 3 - clamping screw.

The diameter of the cut rod is taken to be slightly smaller than the outer diameter of the thread and is sawed down in a cone shape to fit the hole. The selection of rods for cutting metric or inch threads is given in table. 1:

Table 1. Diameter of rods for threaded bolts.

| Metric thread | Inch thread | ||

| Outer diameter in mm | Rod diameter in mm | Outer diameter in inches | Rod diameter in mm |

| 5 | 4,89 | 1/4 | 6,19 |

| 6 | 5,86 | 5/6 | 7,7 |

| 8 | 7,83 | 3/8 | 9,3 |

| 10 | 9,8 | 7/16 | 10,8 |

| 12 | 11,7 | 1/2 | 12,4 |

| 14 | 13,7 | 5/8 | 15,6 |

| 16 | 15,7 | 3/4 | 18,7 |

| 20 | 19,6 | 7/8 | 21,8 |

| 22 | 21,6 | 1 | 25 |

| 24 | 23,6 | 1 1/4 | 31,3 |

| 27 | 26,6 | 1 1/2 | 37,6 |

| 30 | 29,5 | 1 3/4 | 43,8 |

| 36 | 35,4 | 2 | 50 |

Sliding dies (Fig. 3, a) consist of two prismatic halves with a cut hole. In the middle part of the hole the dies make a groove, which forms the cutting edges.

Rice. 3. Sliding dies and crackers:

a - die; b - cracker.

Clamp for thread cutting.

To fasten the dies, a clamp with a rectangular or oblique frame is used (Fig. 4). The prismatic protrusions of the die fit into the grooves of the dies, and the dies are pressed against the sides with bolts.

Rice. 4. Klupp (oblique)

1 - frame; 2 - handle; 3 - clamping screw.

To avoid direct pressure of the bolt on the dies, a so-called cracker (see Fig. 3, b), shaped like a die, is installed between the dies and the bolt.

Die thread cutting technology.

Cutting with prismatic dies is somewhat different from cutting with lerks. When cutting into dies, the rods are not sawed into a cone, but the dies are moved apart.

Then they are clamped on a rod, the end of which should coincide with the upper plane of the dies. By turning the die to the right and slightly to the left, threads are cut.

The position of the holder and clamp is set strictly perpendicular to the rod being cut, otherwise the thread will be oblique and one-sided.

Cooling and lubrication during thread cutting.

When cutting threads with taps and dies, it is necessary to use lubricant. As a lubricant, you can use a regular emulsion, dissolving one part of the emulsion to one hundred and sixty parts of water. In addition, you can use: for cast iron - lard and kerosene; for steel and brass - boiled and rapeseed oil and lard; for red copper - lard and turpentine; for aluminum - kerosene.

It is not recommended to use machine and mineral oils when cutting threads, since they, while increasing the resistance to cutting, do not produce clean holes and lead to rapid wear of taps and dies.

Screw boards.

In order to cut threads on screws with diameters up to 6 mm, screw boards are used. The screw boards have several cut holes of different diameters with grooves for chips, two for each hole.

Thread cutting with dies is performed in the same way as tapping. The rod is firmly clamped in a vice, lubricated with oil, and then a clamp with dies is put on the rod, clamped with a screw and rotated a full turn in one direction and half a turn in the other. If the rod is thicker than required, it must be filed with a file.

Bolt threads are measured using ring thread gauges or a thread gauge.

Thread cutting on pipes and fittings.

Pipes and fittings (connecting parts for pipes) are cut with a special tool using fixtures.

Jig for cutting threads on pipes.

The threads on pipes are cut with a special die (Fig. 5). The device for cutting pipes differs from conventional clamps. Four steel combs fit into the slots of its clip.

By turning the top handle they can be brought closer or apart. Therefore, one die can cut pipes of various diameters. In addition, the die has guides that are adjusted by the lower handle.

The guides ensure the correct position of the die on the pipe when cutting.

Rice. 5. Jig for cutting pipes.

When cutting, pipes are secured with a special pipe clamp. The clamp consists of a frame into which crackers with cutouts for pipes of various diameters are placed.

Threading techniques

Manual thread cutting

The technique for cutting threads on pipe blanks involves the use of the following techniques:

- the use of specialized thread combs and cutters;

- rolling threads using round (flat) dies;

- preparing a threaded connection using “traditional” taps and dies;

- thread cutting using specialized cutters.

Likewise, preparing threaded connections at home is only possible if specific devices and tools exist. In the publication recommended for you, we will look in detail at the method of cutting threads using a special thread-cutting kit (as they also say “kluppa”).

Cutting with an electric clamp

In addition to hand tools, electric tools have also become widespread. The advantage of this design option is high performance. The work when using it has the following features:

- The part to be processed is carefully prepared.

- Ensures reliable fastening of the workpiece.

- The mechanism is attached at the starting point.

- The free movement of the guides and the direction of rotation of the cutting part are checked.

- The first turns are cut in the jog mode.

On the tool you can set basic parameters, for example, the length of the cut. Application features depend on its functionality and other performance characteristics.

Tool and cutting principle

Special tools and devices are used for cutting pipe threads. Most often used:

- pipe cutter;

- dies;

- gates;

- manual clamp;

- sander

To perform an operation on metal pipes, a large mechanical force must be applied, while the pipe must remain motionless. To fulfill this condition, it is clamped in a pipe vice; in cramped conditions, a gas wrench is used for clamping.

Important. The section of pipe to be cut is lubricated with motor oil or technical petroleum jelly. After finishing the work, clean the surface of metal filings and grease with a brush or rag.

To allow the die to rotate, it is secured in a knob. This is a ring with a hole for the die, in which it is fixed with locking screws. The driver has several handles to ensure rotation.

The procedure for cutting external threads on a water pipe

There are water pipes in almost every residential and commercial premises. The sequence of actions when cutting threads is as follows:

- Preparation. At the preparatory stage, the main thing is to remove all dirt and possible rust, as well as remove all defects. Otherwise, difficulties may arise in carrying out the work.

- Installation of the workpiece. The pipe must be positioned strictly vertically, otherwise the die may move to the side.

- Cutting. At this stage, you need to ensure that the mechanism used is strictly vertical, since even a slight displacement can lead to significant problems.

- Quality checking. This stage involves screwing on the nut, due to which the cleanliness of the turns and the accuracy of their location are checked.

When using a lathe, it is possible to create turns in one longitudinal pass. However, screw-cutting lathes are not the best suited for the task at hand.

Types of taps

A device for cutting threads on pipes is called a tap. There are several types of such tools:

- Universal. The operation is performed in one pass. The working part of the device contains teeth, which are necessary for marking and performing final cutting. This tool is suitable for soft metal. When it is necessary to process a material with high strength characteristics, considerable effort is required.

- Complete. This type of device involves the use of various nozzles of the same thread. When working with solid materials, different quantities are used. To obtain the desired result, several steps are performed. First, a marking tap is used. At the second stage, deep cutting is carried out, then the final operation is carried out, which completely forms the edges. It takes much longer to create carvings this way. However, the result is higher quality. Tool breakage during operation is completely eliminated.

Pipe thread classification

The term “pipe” has a privileged position in the plumbing industry. This term is classified with an eye to a group of standards that define the criteria for connections of various elements of plumbing structures.

For example, a pipe thread size is designated by a numerical value indicating the standard bore diameter of the pipe, but not the physical thread diameter.

In practice, pipe threads are used:

- cylindrical (G/BSPP),

- conical (R/BSPT),

- round for shut-off sanitary fittings (Kr),

- inch cylindrical (American standard NPSM),

- inch cone (American standard NPT).

A mechanic whose main work area is household work is recommended to take as a basis the conditional division of pipe threads into two main types:

- cylindrical (G),

- conical (R).

It is these two types that the home plumber most often encounters when servicing household plumbing equipment or laying water supply or heating pipes.

Pipe cutting is carried out in the following cases:

Thread standards

Let's consider several options. It is worth considering that some have ceased to be used in production altogether.

Therefore, we focus your attention on specific types that are in demand all over the world.

G - Straight (inch) pipe thread

In the Russian standardization system it is designated GOST 6357-81, in the world arena – BSPP. These products are in most cases used when working with gas or water pipes and are sold at any retail outlet. As a rule, bronze, steel, or brass plumbing fixtures are equipped with this standard. As for cutting it yourself, you will have to use the English abbreviation.

The advantages are as follows:

G is an international thread mark that is understandable to everyone.

Diameters are calculated in the inch system from 1/16 to 6. The profile angle is 55 degrees, and is slightly rounded upward. The step has only four positions, which we present to you in the table.

| Pitch in mm, P | Number of turns |

| 0,907 | 28 |

| 1,337 | 19 |

| 1,814 | 14 |

| 2,309 | 11 |

The decoding is very simple and you can use it to understand which parameter means what. So:

The first G talks about the type of standard. d or D – nominal diameters in inches. A, B, C – performance accuracy class from maximum to reduced. LH says the product is left hand threaded.

For a complete understanding, you need to familiarize yourself with the table and use it in the future, since it is the values presented that are most often found in home engineering structures.

| Thread size G | Step in millimeters | Diameters (mm) |

| Row 1 Row 2 | d=D d2=D2 d1=D1 | |

| 1/8 | 0,907 | 9,728 9,147 8,566 |

| 1/4 | 1,337 | 13,154 12,301 11,445 |

| 3/8 | 16,662 15,806 14,95 | |

| 1/2 | 1,814 | 20,955 19,793 18,631 |

| 5/8 | 22,911 21,749 20,587 | |

| 3/4 | 26,441 25,279 24,117 | |

| 7/8 | 30,201 29,039 27,877 | |

| 1 | 2,309 | 33,249 31,77 30,291 |

| 1/8 | 37,897 36,418 34,939 | |

| 1-1/4 | 41,91 40,431 38,952 | |

| 3/8 | 44,323 42,844 41,365 | |

| 1-1/2 | 47,803 46,324 44,845 | |

| 3/4 | 53,746 52,267 50,788 | |

| 2 | 59,614 58,135 56,656 |

R - taper pipe thread standard

BSPT is an abbreviation of international significance and is subject to the domestic standard according to GOST number 6211-81.

In its structure, the process resembles the action with a cylindrical workpiece, but only with a slight slope on a scale of 1:16.

According to the state standard, this process must meet the following requirements:

- The profile angle is 55 degrees.

- The step creation corresponds to a specific pipe size.

- The maximum possible diameter of the product used is 6 inches. Wider samples cannot be screwed together; in such cases, welding or flanges are used.

Connecting fittings of this standard are used in places with high pressure and temperature for maximum sealing of the system. Therefore, it is necessary to strictly comply with the standard for the ratio of parameters established by the country.

Other standards

There are several other types, but we will write very little about them, since a citizen most likely will not use them in everyday life:

- Metric cutting, which is not suitable for pipe installation. From the name it is clear that in diagrams and drawings the unit of measurement is the derivative of the meter, that is, the millimeter.

- The letters Kr on the product indicate that this is a plumbing product with a unique profile and smooth round thread.

- NPSM, NPT, NPTF are the designations of the American standardization system. The product has the shape of an isosceles triangle and differs from its analogues in the profile angle, which corresponds to 60 rather than 55 degrees.

Of course, these types of standards are unlikely to be suitable for your work, but it is worth recalling the BSPP parameters so that you can distinguish them from others if necessary.

| Designation of conditional passage | Number of turns per 1 inch | d=D | d2=D2 | d1=D1 |

| 1|8 | 27 | 10,272 | 9,510 | 8,766 |

| 1|4 | 18 | 13,572 | 12,443 | 11,314 |

| 3|8 | 17,055 | 15,926 | 14,797 | |

| 1|2 | 14 | 21,223 | 19,772 | 18,321 |

| 3|4 | 26,568 | 25,117 | 23,666 | |

| 1 | 11 1|2 | 33,228 | 31,461 | 29,694 |

| 1 1|4 | 41,985 | 40,218 | 38,451 | |

| 1 1|2 | 48,054 | 46,287 | 44,52 | |

| 2 | 60,092 | 58,325 | 56,558 |

Rules of procedure

When working with pipes, it is important to stock up on dies with a pipe clamp and a wrench. The die is selected taking into account the type of thread required

This can be determined by checking the stamp or inspection. The dies must be marked. The data on them will give an idea of what brand the tool is made from.

Most pipes require straight threads. Also, before working, you need to determine its direction: right or left. To do this, a letter indicator is depicted on the dies: “L” is left, and “P” is right. The die also indicates what grade of steel it belongs to, this makes it possible to choose the right tool for cutting stainless steel pipes.

The cutting rules are quite simple:

1). Prepare the pipe for cutting. To do this, the chamfer is removed with a file, and the area is treated with an oil solution.

2). Insert the die into the holder, securing it with screws.

3). Bring the die to the product and make several circular rotations in the required direction of the thread.

4). Lightly press down the die to embed it into the material.

Scrolling algorithm:

- 2-3 turns in one direction;

- half a turn to the other.

And so on until the end of cutting

In this case, it is very important to keep the pipe and die strictly perpendicular. Otherwise, the thread will “walk”, which will affect the quality of the connection.

The arrangement of elements, as well as thread cutting, is demonstrated on video and photo materials for better results. Checking thread quality is easy. To do this, it is enough to screw the nut if it is screwed along the outer diameter of the pipe. The most accurate cut is obtained with a sliding die. It will help out if you urgently need to replace a piece of pipe that has a threaded connection.

Also, when choosing dies, it is important to consider what kind of thread will be made, external or internal. High-quality work will allow you to make a sealed threaded connection even in pressure water pipes

Let's sum it up

As you can see, making your own carving using dies is not at all difficult. To do this, it is enough to choose the right tool, put in a little effort and accuracy. Probably, many representatives of the male half of humanity remember how similar problems were solved in labor lessons at school. Therefore, for the majority, it will only be necessary to remember the acquired skills and apply them in adulthood. It’s like riding a bicycle: you only need to learn once to feel confident in the saddle even after a long break.

Manual thread cutting technology and techniques

When cutting threads with taps and dies, part of the metal is not removed along with the chips, but is squeezed out along the cutting edges of the tool, forming a thread profile on the part. Taking this into account, the diameters of holes and threaded rods should not be made according to the nominal thread size, but slightly lower than it. For metric threads with a diameter of 6–10 mm, this difference is 0.1–0.2 mm; with a diameter of 11–18 mm – 0.12–0.24 mm; with a diameter of 20–30 mm – 0.14–0.28 mm.

The diameters of holes for the most common metric thread sizes are given in table. 1.

To form a thread entry at the end of the part, it is necessary to chamfer according to the height of the thread profile.

Table 1. Diameters of holes for cutting metric threads

| Material | Metric thread diameter, mm | |||||||

| 5 | 6 | 8 | 10 | 12 | 16 | 20 | 24 | |

| Steel and brass | 4,2 | 5,0 | 6,7 | 8,4 | 10,1 | 13,8 | 17,3 | 20,7 |

| Cast iron and bronze | 4,1 | 4,9 | 6,6 | 8,3 | 10,0 | 13,7 | 17,1 | 20,5 |

A tap lubricated with grease is inserted into the drilled hole and, lightly pressing it against the part with the left hand, carefully turn the driver with the right hand until the tap grips the metal and its position in the hole becomes stable. After this, the knob is taken with both hands and rotated with the hands intercepted every half turn (Fig. 10, a)

10, a).

Rice. 10. Movements when cutting threads: a - with a tap, b - with a die, c - with a die

After one to one and a half turns, the tap, shaking in a horizontal plane, is rotated in the opposite direction by about a quarter or half a turn. This is necessary so that the chips break and move out of the hole along the grooves of the tap without jamming the tap. Having finished cutting, pass it through or turn the knob in the opposite direction to unscrew the tap from the hole.

The second and third taps are lubricated with oil and inserted into the hole without a driver; Only after the tap is correctly installed on the thread, apply the driver and continue threading.

Thread cutting with dies should be done in the same way. Here, however, in addition to circular movements along arrow a (Fig. 10, b), the knob should also apply some downward pressure along arrow c. During the cutting process, it is necessary to ensure that the pressure on both handles is the same.

At the first stage of thread cutting, you should ensure the correct position of the tap and die in relation to the axes of the hole and the rod. The non-parallelism of the axes and their non-perpendicularity to the end of the part are controlled by a square and are eliminated by changing the position of the tool.

It is necessary to cut threads in small and blind holes of small diameter especially carefully, without overloading the tap and often clearing it of chips. When cutting threads in deep holes, remove the tap from the hole for cleaning (2-3 times). When cutting threads in deep holes, remove the tap from the hole for cleaning (2–3 times)

When cutting threads in deep holes, remove the tap from the hole for cleaning (2-3 times).

If it is necessary to obtain accurate and clean threads on rods, then cutting them should be done with roughing and finishing dies.

If thread cutting is performed with dies with sliding dies, then their compression (feed) should be done only at the beginning of the pass. After each pass along the entire length of the threaded rod, the die is driven in the opposite direction and then the dies are again tightened with a screw and the thread is again cut along the entire length of the rod to be cut until the desired thread diameter is obtained. You should not press the dies in the middle of the rod. Using sliding dies, threads are cut in several passes.

To cut pipe threads with a clamp, the pipe must be securely secured in a special pipe clamp (Fig. 10, c).

The cut end of the pipe is lubricated with oil (linseed oil), and then a die is installed at a length of no more than 2–3 threads, bringing the dies closer together so that the thread is cut to the full depth in 2–3 passes. For diameters up to 1" are limited to two passes; with a diameter greater than 1" a good thread can be obtained only in 3-4 passes. Before each repeated pass, the surface of the thread being cut and the thread of the dies must be thoroughly cleaned with a brush from chips and re-lubricated with oil.

The rotation of the clamp around the pipe is usually carried out with a rocking motion in four steps; For each step you need to turn the clamp 1/4 turn.

Threads with a diameter of up to 1½" are cut by one mechanic; For large thread diameters, two people work together. When working in tandem, a full rotation of the die must also be done in four steps.

187

What should you know about carving?

When installing shut-off valves, adapter tees or couplings on a metal pipe, a thread must be made, which is characterized by the following parameters:

- Depth

- the distance from the base of the thread to the end of the pipe. - The profile and its angle

- the cross section of the coil, which is made in the form of a triangle, rectangle and other shapes. When the side edges of the coils intersect, an angle is formed. - Pitch

- the distance that is formed between the tops of the pipe or nearby turns.

The determination of the profile and pitch should be treated with maximum attention, since the type of thread depends on this:

- Inch

- appears as a triangle and is used when assembling elements of a water pipe, and sometimes a heating pipe. - Cylindrical

is a version of an inch thread that has a smaller pitch. The smoothed top edge of the profile resembles a cylinder. An example of an external cylindrical thread diagram is presented below: - Conical

- the type allows you to obtain a hermetically sealed connection, which is especially important when using sealing materials. - Metric

- this type is used for small diameter pipes. It can be trapezoidal - the outer angle is 30 degrees, and the sides of the coil resemble a trapezoid. For bolted connections, rectangular threads can also be used, since they make the fixation more reliable. Here is a diagram of a metric thread, which looks like an equilateral triangle:

Types of tools

For the manufacture of threaded connections, the industry produces special cutting devices. They are designed to perform certain technological operations. A screw-like tool for creating internal threads is called a tap. The device cuts chip grooves on the body of the pipe. For fastening in the driver, the tap has a long shank. The tool is produced in accordance with the current standard. There are special tables that indicate the size of the tap, its number and type.

The cutting kit includes two taps. Their main difference is the depth of groove cutting:

- Chernova - No. 1.

- Finishing - No. 2.

https://youtube.com/watch?v=K1yjRBdSap4

Die device

This device is sometimes called a lerka. The tool is equipped with a kind of nut with several holes. It is this that creates the cutting edges.

The industry produces lerks of various shapes:

- Klupp.

- Round.

- Split.

- Sliding.

- Whole.

https://youtube.com/watch?v=6Z6h1XBptDE

Description of the clamp

It differs from other devices in its special guide, which centers the die relative to the pipe. The device can be electric or manual. For use at home, when cutting will occur no more than two or three times, it would be more rational to work with a manual clamp. Its cost is much less than an electric tool.

This tool is very convenient to work with. The thread is very clean and reliable. The light weight of the device and the simplicity of the design allow you to quickly replace the cutters.

The most important characteristic of a clamp is the material from which it is made. Expensive tool steel is used to create the die. But carving is created only by incisors. They must be highly durable.

The clamp does not have expensive non-functional elements. Therefore, a set of dies costs much less. The cost of threading a stainless steel pipe is dramatically reduced. Home craftsmen, not wanting to incur large financial losses, prefer to work with such a tool.

Self-cutting

There are several tools you can use to do the job:

- Tap.

- Die.

- Klupp.

Which tool set to choose depends on several factors. This is especially true for the type of carving. After all, it can be internal or external. After selecting a die, there are several steps to follow.

- The old thread is cut off. Don't try to restore it. It will still remain leaky and leakage will occur. The cut should be strictly perpendicular to the longitudinal axis of the pipeline.

- If there are traces of corrosion on the pipe, the segment must be completely removed.

- To make it easier to screw the die onto the pipe, its end must have a lead-in chamfer.

- For easier screwing, the location of the future thread is lubricated with oil.

- After cutting several turns, the die needs to be scrolled back. Performing sequential torsion forward and backward, a thread of the required length is cut.

- After the operation is completed, metal filings are removed.

- To check the quality of work, you need to screw the intended part onto the pipe.

If everything is in order, the number of turns corresponds to the mating part, you can seal the connection and begin installation of the pipeline system.

Hand tools

Manual devices are the main type for thread cutting in everyday life; their use has the following features:

- Availability. Manual devices have the lowest price among devices of this type and are therefore available to any owner.

- Functionality. When applying cutting, a main device (die holder, knob) is used, into which a cutting tool with the required parameters is inserted.

Rice. 5 Bison die and taps in thread-cutting tool sets

Compactness. Manual devices take up little space and do not require large spaces for operations.

The industry produces ready-made sets of taps and dies of different sizes for cutting threaded profiles - this greatly simplifies the task of finding the necessary devices.

Tools for manual processing - tap

The tap is the main device for cutting internal threads, which are rarely used in pipelines. The procedure for working with a tap consists of several simple steps:

- Lubricate the inner walls of the workpiece with machine oil, place the tap in the driver and insert it into the hole, making sure that there are no distortions. The working end of the tap has a conical shape, so there is no need to remove the internal chamfer.

- Make several rotational movements clockwise in the direction of the turns, then rotate the tap back. The procedure is repeated several times, making 3–4 passes back and forth.

- Take the tap out and clean its edges from chips; the same operation is carried out with the inner walls of the workpiece. If the elements are not cleared of chips, the profile teeth may be damaged due to chips getting into the channel.

Rice. 6 Manual pipe threading tool in use

Using the die

Using a die, it is convenient to make external cutting on workpieces of small diameter; before carrying out the procedure, an element with the required parameters is inserted into the die holder, further operations are performed in the following order:

- Using a file, sandpaper or grinder, chamfer the end of the outer walls of the workpiece, lubricate the cutters and the surface to be treated with machine oil.

- Place the die on top of the part and make several turns, trying to keep the tool strictly along the central axis of the workpiece. Then they turn it back and rotate it forward again, covering a greater distance.

- After 3–4 passes in different directions, the die is removed and the surface of the part and the cutters is cleaned of chips.

When cutting with a die or tap, it is rational to use separate elements for roughing and finishing - this simplifies the process and improves the quality of the profile surface of the threaded turns.

Rice. 7 Pipe clamps

Application of the clamp

The die is a hand-held thread-cutting tool, a modern modification of the die and works on the same principle. Its main differences from the die:

- cylindrical guide part with ribs;

- possibility of installation in a special ratchet with a durable, comfortable handle;

- long cutters, with an incomplete section at the edge and gradually turning into the main profile, so the thread is cut gradually, which simplifies and facilitates the work;

- the ability to replace worn cutters in the head with new ones;

- problems when cutting short threads due to incomplete cutting of the surface in the final part. In this case, a die is additionally used or the die is cut to teeth with a full profile.

Carrying out work with a clamp when cutting is similar to actions with a die; it can be turned with a power tool, a ratchet with a handle or an adjustable gas wrench, clamping the ribs of the cylindrical guide part.

Rice. 8 Pipe electric threading dies

Slicing technology

The technology for cutting threaded parts manually and automatically is significantly different.

Die

In order to cut a thread on a water pipe with your own hands using a die, perform the following operations:

- The pipe prepared for cutting is clamped in a vice in a horizontal position.

- A grinder is used to make the end of the pipe even.

- Using a caliper, measure the outer diameter of the pipe.

- They check special tables to find out the required (minimum) diameter for thread cutting.

- Using a grinder, the outer surface of the pipe is cleaned to the required diameter.

- Use a file to chamfer the end.

- The die inserted into the die holder is placed on the pipe with its intake part.

- Pressing the die against the pipe, they begin to slowly rotate the handles of the die holder until the combs of the cutting tool begin to “cling” to the metal and chips appear.

- Subsequently, slowly rotating the die holder with the die clockwise, cut the required length of the threaded part. At the same time, making 2-3 turns clockwise, to reset the chips, turn the die 1-2 turns counterclockwise.

- To ensure that cutting occurs with less effort and that the tool blades do not become dull, a small amount of machine oil is periodically applied to the pipe.

After threading is completed, the die is cleaned of chips. The pipe is removed from the vice and the quality of the work done is checked using a nut or a special gauge.

Klupp

Threading work with a die is carried out as follows:

- The pipe is clamped in a vice in a horizontal position.

- The outer diameter of the pipe is measured and verified.

- Using a grinder and a file, the area for cutting threads is cleaned of rust, old paint, and excess metal.

- The pipe is lubricated with oil or pork fat.

- The clamp is inserted into the frame with a ratchet.

- Using a guide, the dies are installed on the pipe.

- Pressing the frame with the clamp against the end of the pipe, they begin to rotate the handle until chips appear and the force increases.

- After the clamp cutters have caught on the metal, the hand pressing the tool to the pipe is removed and the required length of the threaded part is cut.

During cutting, for every 2-3 turns of the clamp clockwise, make 1-2 counterclockwise - this allows you to dump the resulting chips and avoid clogging the tool cutters.

On a lathe

Work on a lathe can be carried out using a special die or thread-cutting tool:

Cutting the threaded part on the machine is carried out as follows:

- The pipe is clamped into the machine spindle.

- Grind with a simple cutter to the required diameter.

- The end of the pipe is leveled and chamfered.

- The machine is turned off, oil or a special lubricant is applied to the surface of the pipe.

- Place a die fixed in the die holder onto the intake pipe.

- Turn on the machine at low speed and, holding the tool, slowly cut a thread on the pipe.

After the threaded part is cut, the machine is stopped, reverse is turned on, and the die is carefully removed at slow reverse speeds.

Threading work using a special cutter is carried out as follows:

- Using a simple cutter, the pipe is ground to the required diameter, its end is leveled, and a chamfer is removed from it.

- The thread cutting tool is installed in the cutting head.

- Using a special template, the cutting edge of the tool is aligned relative to the installed one, after which it is securely fixed in the cutting head.

- Using special tables, the machine is set up.

- The threaded part is cut in 2-3 steps, deepening its grooves by 0.5-0.7 mm in one cutter pass.

Thread cutting work

To carry out this operation yourself, you need to purchase a pipe threading set. These can be either dies of the required diameter, or a more practical set of dies.

Basic requirements before starting work:

- before threading, the pipe must be cleaned of rust and old paint;

- the lead-in chamfer must be removed on its end surface;

- use only high-quality cutting tools in your work;

- It is imperative to have lubricant for efficient operation of the cutting tool and removal of chips.

Professional pipe threading kit

Preparatory work for cleaning the pipe and chamfering is best done using sandpaper and a file:

- thoroughly clean the surface of the pipe to a metallic shine;

- Use a file to chamfer the end of the pipe.

Cleaning the pipe before threading

The next stage is direct threading, which differs in the sequence of actions, depending on the selected tools.

Using dies

If you purchased dies for cutting pipe threads and a die holder, then the procedure will be as follows:

- we clamp the pipes in a vice, or fix them in a convenient way so that the pipe remains motionless during the cutting process;

- install the die into the die holder and fix it with screws;

- apply oil to the pipe and to the cutting edges of the die;

- carefully place the tool on the pipe and, rotating clockwise, cut the first thread pitch;

- We make sure that the tool is perpendicular to the pipe;

- Having cut the thread to the required length, unscrew the die and run it again.

Thread cutting with a die

Application of the clamp

A simpler version of thread cutting can be achieved using a die. This is a modernized die, equipped with a special guide and ratchet. Most often sold as a pipe threading kit.

The cutting process will be as follows:

- install a screw of the required diameter from the purchased set into the ratchet;

- apply oil to the cutting edges;

- We put the guide on the edge of the pipe;

- we begin to twist the ratchet, cutting the thread;

- lubricate the pipe and cutting edges during operation.

Cutting pipe threads using a clamp

Thread cutting

Tools

Explanation. A thread-cutting tool for pipes and fittings in the form of a thick plate with a threaded hole in the center is called a thread-cutting tool. Where there are slots to form cutting edges. A die, unlike a die, is a one-piece tool, therefore, the carving is more accurate, especially on blanks with a small cross-section. It can be for cutting left-handed or right-handed threads, but there is also a universal option - marked LN.

Clutch with ratchet

- As you understand, the main device used for cutting threads on pipes is a lever, but by itself it is not effective, since it requires a lever to activate it . You can immediately make a reservation that the lever must be specialized, for example, if you clamp it with a gas wrench and try to cut the thread, the lever will most likely burst.

- The cutting tool is fixed in a clamp - this is a frame with handles - so, the frame compresses a prismatic or square blade, increasing its strength, and the handles, screwed on the sides, serve as a lever . But such a device is convenient in cases where there is room for levers, but if the blank is located against the wall, then they have to be constantly unscrewed and tightened again. Therefore, here it is much more convenient to use a pipe clamp with a ratchet, as in the photo above - the presence of a wall on one or even both sides (corner) in this case will not be a serious obstacle.

Electric thread cutting die SQ30-28

- An electric clamp or machine for cutting threads on pipes is also a hand tool that can be used in any plane, moreover, the head can be inserted from any side, therefore, both sides are working . Thanks to the powerful gearbox, you will hardly have to exert any effort when cutting threads, but its price, accordingly, is also much higher than the same ratchet. Despite its versatility, such a tool, compared to a lever die, is quite bulky and requires operational space for cutting threads on a blank.

Practical advice

First of all, the instructions require cutting the pipe evenly, since otherwise the thread will move diagonally, therefore, the thread will be unclear, with a broken pitch, or you will not be able to catch the edge at all.

Here, especially if the blank is located against the wall, no markings will help you - for an even cut you need to develop an accurate eye. Even if you didn’t succeed in making an even cut the first time, you can always use the same disk to trim the higher edge so that you get an angle of 90⁰ with respect to the pipe wall.

It is very important to pay attention to the condition of the metal - given that such work is usually carried out with old plumbing or heating, the walls can be corroded, and cut threads will make them even thinner. Therefore, you should either get to the “living metal,” as craftsmen usually call it, or even replace the old pipe with a new one.

On an even cut, you need to remove the chamfer, which will allow the blade to “catch” on the metal, just try to ensure that the bevel is uniform around the entire circumference - this way the head will screw on evenly.

Recommendation. To cut a thread, it is imperative to lubricate the working blank so that the edge does not become “torn.” For this, machine oils and grease are used, but practice shows that the best lubricant in such cases is raw lard, which is rubbed onto the surface being treated.

We use a clamp with a ratchet

Cutting threads for risers standing next to the wall

Tell us, what do you use to cut the threads on the risers standing close to the wall? You’re tired of fiddling with Soviet dies, but you can’t get anywhere. I’m tormented by vague doubts that there’s probably something on sale. Can you enlighten me?

yes .. bosch gbh 5-40 . They work on a hole in the wall and then go ahead with the clamp.

2SpiKeR If you can’t crawl up with a hammer, hammer the wall so that you can crawl up.

Gebo adapters rule

What does the adapters have to do with it?? Welding won’t work, we’re installing polypropylene. Is it really just a matter of making a sample near the pipe, some people have tiles installed, they’re such budget repairmen. So it won’t always work like that.

During budget repairs, the risers are not touched.

I don’t understand why the PP here is welded with threads or I definitely didn’t understand something

and where exactly on the riser?

what does this have to do with it? As far as I understand, you need to get a thread from the cut riser at the outlet, right? If so, then these adapters are specifically designed for connection to steel pipes. I cut the pipe straight, removed the bead, sanded off the area of paint under the fitting, put on the fitting, clamped it with the butt and then use either propylene or butylene. If it’s important to you EXACTLY to cut the threads, then go ahead, Shura, go ahead and gouge the walls.

I’m sorry, I didn’t understand right away)) If possible, then in more detail from this place! Even without budgetary repairs, they touch it if it becomes necessary, it slowly crumbles. People would rather sit without repairs, but with water.

There are Gebo adapters for connecting to steel pipes. collet connection principle. convenient thing. Google where you can buy it in your city. By the way, they are made of cast iron.

Oh how. Why the hell was I cutting threads and struggling? But, IMHO, collets are only suitable for a perfectly cylindrical pipe. How can you know its geometry in advance? And if there is rubber or any other elastic material as a seal, then this is a threshing floor. It’s better to get it done with thread cutting.

Just pierce the wall and hold the die with a ratchet just right, with one handle you can cut the thread.

If the socket and ratchet do not fit, you can use only the socket and rotate it beyond the edge with an open-end wrench

I don’t remember what the tolerance in mm is for the deviation from the cylinder. But fittings with German certification. There are several seals, including rubber, or rather EPDM. Whether to trust them or not is a personal matter for everyone. But for me personally, the DVGW mark already means that there is no point in asking further questions about quality. And, by the way, it is not a fact that the Gebo adapter will leak before the pipe cracks along the cut thread. The advantage is that there is no weakening of the pipe (thread cutting is the weakening). Although, of course, you shouldn’t wall them (adapters). Still a collet.

Comments

April 20, 2017

Mikhail

In the garden, a dilapidated iron pipe, dilapidated, under pressure, sticks out vertically. It was clogged with a wooden cork, rotten. I want to install a faucet. What you need to buy and what to do (in order). Thank you.

0 0 Reply

April 20, 2017

Mikhail (o-trubah.ru) ➜Mikhail

If the pipe is dilapidated, it should ideally be replaced at the point where it joins the main pipeline. But in any case: We turn off the water, because you still won’t be able to work under pressure. Cut the pipe to the desired height. We cut a thread on the pipe or weld an elbow. We install an angle onto the thread, or - if we welded an elbow - immediately install a tap. We seal the connection with plumbing tape. After applying pressure, check the degree of tightness: there should be no dripping from the connections.

0 0 Reply

Will need

- Clamp for the required pipe diameter.

- Adjustable wrench (gas).

Klupp is a thread-cutting tool, like a die, only it is an attachment with a guide skirt. It must be purchased from a plumbing store. There is no shortage of them, so you can find them without problems, even in the village.

In this case, the Chinese version is presented, which is quite good.

Such a thing costs around 200-500 rubles. It all depends on the diameter and markup. Running models with diameters of 1/2, 3/4 inches and inch, as in my version.

You can ask plumbers for a Soviet equivalent, if possible. Then it will be completely free for you.

Main reasons for marriage

The cause of defects in work is the inattention of the worker or the use of low-quality tools. Common pipe cutting defects when working with a tap or die:

- Torn threads - a problem occurs when using a dull die, untimely removal of chips, or insufficient lubrication.

- Incomplete thread - the diameter of the thread hole exceeds the recommended one.

- Skewed helical grooves – incorrect installation of the die or tap.

- Thread failure is caused by clogging of the grooves with chips, poor quality of the tool, or the pipe diameter is larger than specified.

- Tap failure - excessive force applied in a narrow hole, insufficient chip removal, lack of lubrication.

Self-preparation of parts for threaded connections is quite accessible if you have the tools. In order for the work to be done efficiently, you must follow the rules. The use of sharp tools and accuracy compensate for the lack of professional skills.

Inch and metric cutting

Several parameters are considered to be a characteristic difference:

- The part measurement is expressed in inches.

- The thread profile resembles an isosceles triangle, the apex of which is 55 degrees.

- Features a large step.

- Large profile.

- High strength.

In Russia, all measurements are performed in the metric system. Threading a threaded connection was no exception. The characteristic differences are:

- Dimensions are indicated in millimeters.

- The profile resembles an equilateral triangle.

- A small step.

To connect water pipes, the inch system is used, the manufacture of fasteners is done in the metric system. If the reinforcement is screwed in a clockwise direction, the connection is called right-handed. If on the contrary, the thread is considered left-handed.