Residents of holiday villages and rural settlements from time to time are faced with the need to pump out dirty water containing a large number of various types of insoluble inclusions, including long-fiber ones.

A borehole or sump pump designed to work only with clean water will be useless in such a situation.

Here you need a special unit, which is called a surface pump for pumping out dirty water. Let's consider the most affordable and easy-to-use type of this equipment, namely a surface pump for dirty water, and learn how to choose it correctly.

Variety of pumps

Structurally, drainers are divided into two large groups: surface and submersible. As the name suggests, submersible models are lowered into water for operation and have the following properties:

- They are characterized by greater power and greater pressure, since they work at great depths.

- She is irritated by noise, since the sound of the operating device is muffled by the thickness of the water.

- Submersible models are characterized by relatively low weight and compact dimensions.

- Reliable and strong, they still require regular maintenance. The reason is the conditions in which the mechanism has to function.

Surface models have the following features:

- They are noisier than submersible ones. Sound is not perceived as a disadvantage, since the unit operates outdoors and not in an apartment, and sound waves are dissipated in space.

- Convenient to use. They do not have to be immersed in the pumped liquid and then removed from there.

- In terms of power, they lag behind submersible models and are not designed to work at great depths.

Submersible pumps have a vertical design Source nasosovnet.ru

Submersible pumps have a wider range of uses, and they are equally useful for both water supply and wastewater disposal. It would be a mistake to consider all submersible pumps to be drainage pumps. If you have little idea how to choose a drainage pump so that it does not turn out to be useless due to technical limitations, it is useful to get acquainted with the classification of drainers. According to the method of application, they are divided into the following types:

- Drainage They are used for pumping and collecting water of varying degrees of contamination. They work at depths of up to 7-10 m, in tanks, basements or in reservoirs.

- Fecal. Structurally, they resemble drainage analogues, but have a greater reserve of power and strength; some models are equipped with a chopping knife. They are used for pumping fecal and heavily polluted water; many models have restrictions on maximum inclusions (for example, up to 35 mm in size).

- Wells. They are engaged in pumping clean water (inclusions no more than 5 mm), can work at different depths; lifting height starts from 7 m.

- Borehole. Designed for operation at great depths, therefore they are distinguished by high power, operating pressure and productivity.

Scheme of operation of a well drainage pump Source kolodec.guru

Surface-type unit for pumping out wastewater

Installation of such pumps is carried out indoors, which are reliably protected from moisture and frost. The best option for placing this equipment is premises located in close proximity to the cesspool.

Such pumps have certain advantages:

- mobility. Such pumps can be used not only for pumping wastewater, but also for other purposes;

- Compared to submersible pumps, these units have lower power. Therefore, using them for domestic purposes, you can save electricity;

- a mechanism for grinding small waste, as well as large, medium-sized fecal matter;

- acceptable cost.

Drainage pump: features and design

Ratings of drainage pumps are compiled annually, taking into account the technical characteristics of various models. However, despite the difference in parameters, they are all capable of coping with many tasks of pumping clean, rain, melt, drainage, and ground water, namely:

- Drain slightly contaminated or waste water from a pit, swimming pool, or drainage ditch.

- Remove water from a reservoir, well or open pond for watering plants or cleaning the area.

- Pump out sewer water (some models).

- Pump out water with impurities (silt, clay, suspended sand and dirt) from the basement after flooding.

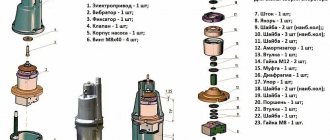

The difference between submersible drainage pump models and their surface counterparts is their greater power and performance; their cost is also higher. The unit structure includes the following elements:

- Frame. It is made of stainless steel or impact-resistant plastic, contains an electric motor and a suction unit.

Drainage pump and its components Source storgom.ua

- The engine is most often located vertically. An impeller (impeller) is attached to the electric motor shaft. As the wheel rotates, it creates a pressure difference; under the influence of centrifugal force pressure, the water flow moves into a pipe or outlet hose.

- The pump unit is equipped with an intake pipe and a grill. Its purpose is to filter out large particles that can harm the device. The diameter of the holes in the grid determines the size of particles that the unit can handle.

- The pump kit includes an electrical cable (at least 10 m), which facilitates the use of the unit.

When deciding which submersible pump for dirty water is best to choose, it is useful to determine the scope of its use. The fact is that the device is specific equipment, and it is not recommended to use it for other purposes. For example, it can be used to clean a shallow well, but this should be a one-time task; such a pump is not intended to operate in a well. Also, a submersible drainage pump cannot be used for pumping out sewage - it will quickly fail.

Pumping groundwater from the basement Source drydesigns.co.uk

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

Compact pumping stations for domestic use

For the uninterrupted and efficient functioning of autonomous water supply systems for dachas and private houses in automatic mode, compact pumping stations have recently been increasingly used. The use of such stations, which include several technical devices, makes it possible to minimize human participation in controlling the operation of pumping equipment due to automation elements. The compact dimensions of household pumping stations for pumping water, which, despite their small size, are characterized by high performance and are capable of creating good pressure in the pipeline system, allow such equipment to be installed in any convenient place, including in the basement of a residential building.

The household pumping station includes the following technical devices:

- submersible centrifugal pump that pumps water from an underground source;

- a filtration unit in which water from an underground source is purified from solid inclusions;

- a circulation pump designed to pump water from the filter unit to the station’s hydraulic accumulator;

- a hydraulic accumulator, the internal chamber of which, filled with water, is equipped with a special membrane (the task of this device is to maintain constant pressure of the liquid medium in the autonomous water supply system, as well as to provide this system with water in those moments when the station pump does not work due to a breakdown or lack of power).

Automatic pumping station for individual water supply systems and small garden plots

The operation of a household pumping station in automatic mode is ensured by a pressure switch, which automatically turns off the pumping equipment if the level of water pressure in the accumulator rises to a critical level, and also turns it on when such pressure drops below the permissible value.

Mini-pumps are actively used not only in everyday life, but also in industry, in particular in food industry enterprises. To pump liquid and viscous media used in technological processes at enterprises in this industry, special food pumps are needed, the structural elements of which are made of materials that are highly resistant to oxidation and do not release harmful substances into the pumped medium.

Characteristics

When comparing different models to determine which sump pump is best, it is important to remember that standard units have several common properties:

- Pollution should be light. During operation, the volume of solid impurities inside the drainer should not exceed 10%.

- The size of particles in the impurity for different models ranges from 3-40 mm.

- The devices are not intended for pumping hot water; household models are designed for an operating temperature of a maximum of 35-40°C. If the heating plant breaks, the standard pump cannot be used. The possibility of pumping hot water is indicated in the instructions.

The particle size is determined by the size of the hole through which the device draws water. Therefore, size is an indirect parameter by which you can understand what kind of water the pump is intended for:

- Impurities up to 5 mm. The device can handle lightly contaminated water from a swimming pool, irrigation tank or other reservoir with a low content of foreign particles.

- Impurities up to 30 mm. The pump will be able to drain a flooded basement or pit (under the foundation).

Each pump is designed for a certain level of impurities Source ytimg.com

- Impurities up to 50 mm. The unit is suitable for pumping melt, rain, and waste water from pits, ditches, and lowlands on the site.

If you plan to pump water from a depth of more than 5 m, then a surface pump will not cope with this. You will need a submersible unit whose technical characteristics are described as follows:

- Electric motor power. The most important characteristic on which performance depends. For domestic needs, models with a power higher than 1 kW are rarely purchased; usually it ranges from 300-800 W. In some instances the power reaches 1.4-2 kW.

- Performance (throughput). Shows how many liters the pump pumps per minute or hour. Household models pump 150-250 l/min (up to 15 cubic meters per hour), some have a capacity of 400-500 l/min.

Pump for pumping out a septic tank Source my-farmer.ru

- Height of water rise. The pressure is easy to determine for a well; for other cases a calculation is needed. For example, if you have to pump out a basement 3 m deep, but a hose with water needs to be laid along the area (15 m horizontally), and then thrown over a fence 2 m. The required pressure is obtained from the addition: 3 + 15 x 0.1 + 2, where 0 ,1 – coefficient for horizontal sections. The value of 6.5 m is the pressure required for this task.

- Immersion depth (pump). A technical characteristic that should not be confused with lifting height; as a rule, they do not coincide. The immersion depth can be either greater or less than the lifting height; this should be taken into account when studying the technical passport.

- Material. Sometimes water contains active impurities (chemicals). Manufacturers take this possibility into account and use materials in production that are resistant to aggressive environments and corrosion. Stainless steel or especially durable plastic is selected for the body. Under normal conditions, the materials behave almost identically, but in an aggressive environment, stainless steel is preferable, and such a pump will cost more.

The metal case is more reliable in operation Source pearl-kamchatki.rf

- Water resistance. One of the characteristics is the degree of protection, which is expressed in international classification, for example, IP68 or IPX8 marking.

- Minimum residual liquid level. No more than 40-65 mm.

- Hose. The hose is selected separately, and it is important to ensure that its diameter matches the diameter of the pump nozzle.

It is important to remember that running dry without water, even for a few minutes, can damage any pumping equipment. To protect against dry running, drainage pumps are equipped with a float switch. It is an important and reliable element of automating the process and protecting the mechanism from damage. The float switch has two operating modes:

- When there is a lot of water. At this moment, the mechanism is turned on (the contacts are in a closed state), and the pump continues to function.

- When the level drops to critical. The float drops, the contact opens (a steel ball is used for this), the engine stops.

Float switch operation diagram Source ampika.ru

Gilex Drainer 220/12

Photo: https://beru.ru/

Compared to previous models, the cable length here is 7 m, so it cannot pump out all pits to the bottom. This is a good option for clearing groundwater from basements, as well as for irrigating vegetable gardens. The device has a compact size, so it fits easily even in small holes. The plastic body is a little unusual, but this is a big plus due to its resistance to corrosion. The equipment has a long service life, in particular due to the automatic stop of operation using a float switch when the liquid level decreases.

Drainage pump Drainage 220/12 (590 W)

Advantages:

- fast work

- Easily pumps out pools

- sophisticated overheating protection system

- reliable water cooling

- housing tightness

Flaws:

- high power consumption

And this is where our TOP comes to an end. We hope that we were able to find the right device for your pool.

#Top 10

Read us first - add the site to your favorite sources.

Add a comment

{"commentics_url":"\/\/express-novosti.ru\/comments\/","page_id":1253621,"enabled_country":false,"enabled_state":false,"state_id":0,"enabled_upload": false,"maximum_upload_amount":3,"maximum_upload_size":5,"maximum_upload_total":5,"securimage":true,"securimage_url":"\/\/express-novosti.ru\/comments\/3rdparty\/securimage\ /securimage_show.php?namespace=cmtx_1253621″,”lang_error_file_num”:”\u041c\u0430\u043a\u0441\u0438\u043c\u0443\u043c %d \u0444\u0430\u0439\u043b\u043e\ u0432\u043c\u043e\ u0436\u0435\u0442 \u0431\u044b\u0442\u044c \u0437\u0430\u0433\u0440\u0443\u0436\u0435\u043d\u043e.","lang_error_file_size":"\u041f\u043e \u0436\u0430\u043b\ u0443\u0439\u0441\u0442\u0430, \u0437\u0430\u0433\u0440\u0443\u0437\u0438\u0442\u0435 \u0444\u0430\u0439\u043b \u0440\u0430\ u0437\u043c\u0435\u0440\u043e \u043c \u043d\u0435 \u0431\u043e\u043b\u0435\u0435 %d MB.","lang_error_file_total":"\u041e\u0431\u0449\u0438\u0439 \u0440\u0430\u0437\u043 c\u0435\u0440\ u0432\u0441\u0435\u0445 \u0444\u0430\u0439\u043b\u043e\u0432 \u0434\u043e\u043b\u0436\u0435\u043d \u0431\u044b\u0442\u044c \ u043d\u0435\u0431\u043e\u043b\ u0435\u0435 %d MB.","lang_error_file_type":"\u041c\u043e\u0436\u043d\u043e \u0437\u0430\u0433\u0440\u0443\u0436\u0430\u0442\u044c \u0442\u0 43e\u043b\u044c ""lang_text_loading":" u0437\u043a\u0430 ..","lang_placeholder_state":"\u0420\u0435\u0433\u0438\u043e\u043d","lang_text_country_first":"\u0421\u043d\u0430\u0447\u0430\u043b\u0430 \u0432\u044b\u04 31\u0435 \u0440\u0438\u0442\u0435 \u0441\u0442\u0440\u0430\u043d\u0443″,”lang_button_submit”:”\u0414\u043e\u0431\u0430\u0432\u0438\u0442\u04 4c","lang_button_preview":" \u041f\u0440\u0435\u0434\u0432\u0430\u0440\u0438\u0442\u0435\u043b\u044c\u043d\u044b\u0439 \u043f\u0440\u043e\u0441\u043c\u 043e\u0442\u0440″,”lang_button_remove ":"\u0423\u0434\u0430\u043b\u0438\u0442\u044c","lang_button_processing":"\u041f\u043e\u0434\u043e\u0436\u0434\u0438\u0442\u0435..."}

Criterias of choice

Performance characteristics are the main information when evaluating different models of gray water sump pump; To choose the option that's right for you, you should follow the following strategy:

- Rely on key parameters: power and pressure. For country needs, 5-10 cubic meters per hour is quite enough, and for watering beds you can get by with 0.4-0.6 cubic meters.

- Pressure helps you understand how far you can transfer water. Keep in mind that 1 m vertically approximately corresponds to 10 m horizontally, so it is useful to measure the distances on the site in advance.

Pumping water from the basement Source samstroy.com

- If you compare models based on performance, consider the time it will take to complete a particular task, and focus on the most difficult task.

- The choice of manufacturer is a matter of personal preference of the owners. Some trust only well-known (and, preferably, foreign) brands, while others find models with a good price/quality ratio from domestic manufacturers.

Popular manufacturers

Pumping equipment is widely in demand in all areas of technology, industry and everyday life. Therefore, it is impossible to list all manufacturers.

Let's consider only the most famous companies producing specialized equipment for swimming pool maintenance:

| Manufacturer | Country of Origin | Pump type | Price range |

| BESTWAY | China | Submersible (drainage type) | Low, medium |

| INTEX | China | Submersible (drainage), surface | Low, medium, high |

| AQUAVIVA | China | Superficial | Average |

| KRIPSOL | Spain | Superficial | Medium, high |

| HAYWARD | USA | Surface, stationary | High |

| ASTRALPOOL | Spain | Surface, stationary | Medium, high |

| EMAUX | China | Superficial | Low, medium |

According to the table, you can see the specifications of some manufacturers for small household pools (Bestway, Intex) and for larger, stationary models.

Rating

In suburban areas, far from the benefits of civilization in the form of water supply and sewerage networks, the pump is a source of familiar comfort, and its choice is approached especially carefully. Help in choosing is provided by ratings of drainage pumps for dirty water, which are compiled by both specialists and ordinary users.

Watering the garden is one of the functions of pumping equipment Source grounde.ru

How to prevent water penetration

To get rid of water in the basement, homeowners can be advised to use several modern methods aimed at combating liquid penetration. The first of them involves the creation of a ring drainage, which is placed at the level of the base of the foundation around the walls and helps to ensure that liquid is retained by the drainage system. The second is the use of waterproofing applied to the floor and walls. The waterproofing layer will become a serious obstacle to water penetration.

This is interesting: how to get rid of water in the cellar without a pump.

Video description

About the Grundfos Unilift Kp 250 m1 pump in the following video:

- AL-KO Dive 6300/4. A high-pressure pump with a capacity of up to 6300 l/h and a maximum flow of 40 m, suitable for use both in irrigation systems and for installation in a well. The device is designed for long-term operation, as evidenced by the stainless steel motor shaft. One of the disadvantages is the problematic check valve.

- VORTEX DN-900. The unit is used for pumping clean, rain, drainage, and groundwater. The advantage is its power of 900 W, a throughput of 15.5 cubic meters per hour, as well as protection against dry running and overheating. The disadvantage of the model is the leaky housing, the reason for frequent repairs and relatively quick failure.

- PATRIOT F 850. The vertical immersion model is designed for pumping dirty water (with impurities up to 35 mm). The advantages include automatic silent operation, a stepped diameter of the outlet pipe, and excellent engine tightness. Cons: the float can become clogged with silt, the body is made of plastic, the impeller is also plastic and therefore fragile.

High pressure pump AL-KO Dive 6300/4 Source vencon.ua

VORTEX DN-750

Photo: https://beru.ru/

A reliable drainage pump that is capable of maintaining pressure in the water supply system and supplying water to consumers. It turns on and off independently depending on flow. Can work with contaminated water, passing particles up to 25 mm. The outlet pipe is universal - any hose will do. Impact-resistant plastic is not afraid of corrosion. The float mechanism reacts to the water level - when low, the unit turns off, when high, it turns on. It has a temperature sensor built into it; if the motor overheats, protection is triggered and it turns off.

Drainage pump DN-750 (750 W)

Advantages:

- powerful

- can be used in water supply system

- strong pressure

- quiet

Flaws:

- soft plastic

Briefly about the main thing

Drainage pumps, originally created for draining basements, have now significantly expanded their scope of application. They can be found in wells and swimming pools, cleaning pits, basements, and pumping wells.

Submersible models have an advantage over their surface counterparts when lifting water from a well, but they are more difficult to maintain. In a suburban area, drainage specialists are responsible for a lot of work, which is why a competent approach to their selection is so important.

When comparing different versions of devices, pay attention to their main characteristics: power, height of water rise, ability to pump impurities. A suitable model is determined based on the type of work planned; for large volumes of work, pumps with a stainless steel housing and motor shaft are preferred.

Ratings 0

Grundfos Unilift KP 150-A1

Photo: https://beru.ru/

Submersible drainage pump for handling slightly contaminated liquids. The size of permissible solid inclusions is 10 mm. Larger particles are retained by a mesh at the base of the drainage basin. The case is made of stainless steel. The asynchronous motor is cooled by passing fluid. Thanks to this, it can work indefinitely without overheating. 1¼" outlet. The float switch turns the unit on and off when it reaches a certain level. The motor is protected from overheating, turns off in case of overload and turns on again when it cools down to normal temperature.

Drainage pump Unilift KP 150-A1 (300 W)

Advantages:

- stainless steel housing

- immersion depth – 10 meters

- high permissible temperature – 50°

- compact dimensions

Flaws:

- high price

Installing a waterproof barrier in the basement

There is a solution to the problem of basement flooding in houses on flat areas, which, although it does not eliminate the cause itself, like drainage, allows you to completely do without any temporary devices. We are talking about organizing a waterproof barrier inside the basement - essentially a “trough” over the entire surface of the walls and floor. How this is done will be discussed further.

Generally speaking, there is no need to make such a barrier along the entire height of the basement walls. It is enough to raise its level 100 mm above the highest groundwater level. Of course, you can simply make a barrier to the soil level - water simply cannot rise higher, but the high price of the materials used in this method requires corresponding savings, and this can only be achieved by avoiding overspending. Accordingly, the first thing that needs to be done is to determine the level of the primer and, thereby, determine the upper limit of waterproofing.

Next, you need to decide what exactly needs to be done to create a waterproof barrier. There are two options here:

- If the basement is a reinforced concrete monolith-trough, poured in one go, then it will be enough to treat it from the inside with impregnating waterproofing. This is a special mixture that penetrates into the pores and microcracks of concrete and contains additives that crystallize in water. The crystals formed clog all the pores in the concrete, thereby forming a waterproof barrier - what we need.

- Any other case, including a reinforced concrete monolith poured several times, because even this option cannot be considered a full-fledged monolith, since each new pour over the existing concrete creates a highly permeable boundary between different layers; for water it is, in fact, almost a crack. Penetrating waterproofing, which clogs only microcracks and pores, will be powerless here. What can we say about all sorts of combined options, for example, walls made of concrete blocks or bricks, the floor is a monolith. In this case, it is necessary to make an additional inner layer of waterproofing materials. Coating or adhesive waterproofing is not suitable here, since it has an increased risk of peeling, especially under water pressure. It is necessary to use materials that have high adhesion to concrete and brick surfaces and create a high-strength layer that does not crack over time. This is exactly the option we will consider.

First, let's decide on the necessary materials and tools. We will need:

- Sand concrete mixture.

- Impregnation waterproofing.

- Reinforcing waterproofing.

- Mixer and kneading container.

- Brushes, rollers, brushes.

- Spatulas.

Let's get to work.

We have a basement with walls made of concrete blocks, the floor is a monolith, which was poured after the walls were built. When spring comes, the basement floods. By the way, this also happens in case of prolonged rains.

It is quite obvious that the main problem areas are the junction of the walls with the floor and the tile joints.

1. Pump out water from the basement. This can be done manually or using any suitable pump, such as a baby pump. Please note that they come in two types: with lower or upper water intake. It is clear that it is better to use with the lower one. By fixing it vertically, you can pump out almost all the water. In our case, there was no such pump, so pumping had to be done in two stages: pumping to the minimum possible level - approximately 30 mm, and manual residual pumping.

As the pump drains, it will emerge from under the water. Very important! It only cools down when it is in water, so you need to constantly water it to keep it from overheating. Next, we place the pump in a large bucket, where we scoop out the water with a suitable tool.

We sweep the remaining water into one puddle with a brush and pump it out in the same way. As a result, we get an almost dry room. The water, of course, will rise. If the work is done slowly and does not interfere, then you can move on to the next stage. Otherwise, the work will have to be postponed until a more suitable time.

2. We process the junctions of walls and floors, as well as seams. We mix the sand-concrete mixture and use a spatula to form skirting boards with a height and width of about 40–50 mm along the entire perimeter of the room. We putty the seams between the slabs with the same mixture. Leave to dry. The next day, when the baseboards are in place, we move on to the next stage - treatment with impregnating waterproofing. High humidity in the room will not hurt - the impregnation works in water, the main thing is that there are no puddles. We pump them out using the method described above.

3. Mix the waterproofing mixture with a mixer according to the attached instructions.

4. Use a brush to cover the entire surface to be treated with the resulting creamy mass.

Leave to dry. After the time specified according to the instructions, apply the second layer. After treatment, water will not flow through the surface of the concrete - these are the planes of the blocks and the entire floor. The seams and junctions remain. We will process them when the second layer of penetrating waterproofing dries.

5. If necessary, pump out the water again.

6. Mix the armoring solution according to the instructions.

7. Similar to penetrating waterproofing, apply the resulting solution with a brush to the entire surface to be treated. We pay special attention to the seams between the slabs and the junctions.

8. The first layer is the base layer. It is necessary to wait the required time for setting and apply the second layer. Before this stage, all flaws will be clearly visible, in the form of oozing microholes. The water leaves clearly visible marks; in the photo there is a whitish stripe. In this case, the location of the leak can be seen.

The result is puddles that need to be drained.

9. Mix the solution a little thicker and treat the leakage areas. Fill the floor with the next creamy mixture. It is convenient to distribute the finished mixture with a roller:

or with a flat brush:

As a result, we get a very durable, absolutely waterproof layer of waterproofing.

If after the second layer there are still holes with oozing water, then you need to repeat the procedure in the leakage areas as many times as necessary. Usually after the third layer there are no such places left.

So, the described methods for draining the basement will certainly allow you to get rid of unnecessary water and protect the internal basement from high humidity, but which option to use must be decided individually, based on specific cases and goals.

Drainage arrangement

This method is good because it allows you to combat the root cause of flooding - high groundwater levels. The result of the work will be its reduction. Unfortunately, this method is not applicable in every case. To understand why, let's take a closer look.

A drainage system is essentially a drainage system through ditches or special drainage pipes. Deep ditches on a site are dangerous and do not enhance its appearance, so they are not used for domestic purposes. With their help, you can, for example, drain a swamp in order to organize a place for a vegetable garden. Let's consider a system of pipes. A drainage pipe is a pipe of large diameter, at least 100 mm, with a network of small holes across the entire surface, buried to the drainage depth, that is, below the basement floor level, with a slope away from the house and a free exit. Thus, the use of such a system is possible only in areas that have their own slope. It is this that will ensure the natural flow of water and its free exit at the end.

Conclusion: if you have the opportunity to make a drainage system around your home, then it is necessary to do so. Either alone or in combination with other basement drainage measures, it will give excellent results and eliminate the root cause of flooding.

Safety rules at work

When working with pumps, safety rules must be followed. First of all, these are the standard requirements when working with electrical installations:

- serviceable wires, insulation, switches;

- presence of a grounding conductor;

- correspondence of the network voltage with the installation parameters.

In addition, special requirements must be taken into account:

- there should be no people in the pool bowl while the pump is operating;

- Do not leave a working device unattended;

- operating conditions must comply with the manufacturer's requirements (temperature, supply voltage, etc.).