- for crimping, you need two wrenches of the appropriate size;

- for press fittings - crimping pliers.

Manual crimping pliers or press, device for cutting MP pipes and calibrator. Actually, this is all the tools necessary for installing press fittings and installing metal-plastic pipes

Basically everything. Instead of a pipe cutter, you can use a saw with a metal blade, but you will need to make cuts strictly perpendicular to the surface. If you don't trust your eye, take a carpenter's miter box.

Preparation procedure

Metal-plastic pipes of small diameter are sold in coils. Before installation, a piece of the required length is cut from the coil. In this case, it is necessary to take into account the length that extends onto the fitting. That is, you need to cut off a piece with a small margin - 1.2-1.5 cm.

The edges of the section are inspected, if there are burrs (there are no burrs when cutting with a pipe cutter, this is a drawback when cutting with a saw), they are leveled. Next, using a chamfer tool or a piece of sandpaper, they remove the chamfer - grind the plastic at an angle both inside and outside the pipe.

We cut, calibrate, chamfer

After this, they take the calibrator, forcefully drive it into the pipe and turn it, align the geometry, at the same time straightening the edges that are “crushed” inward. After this, you can begin installing metal-plastic pipes and fittings.

How to level a piece of metal-plastic pipe

As already mentioned, this type of pipe comes in coils, that is, they are twisted. After cutting a piece, you will straighten it a little with your hands, but how to achieve perfect evenness. This is important if the pipeline installation is open. The recipe is simple:

- Find a flat board or piece of chipboard, plywood, etc.

Usually, when laying out a water pipeline, the route has to be bent in some places, and straight sections have to be laid in some places

After the segment becomes smooth, you can calibrate its edges.

Installation of metal-plastic pipes using compression fittings

Compression fittings consist of several parts. The base is a cast body with threads. There is also a ferrule that secures the piece of pipe to the fitting and a union nut that clamps the connection. An important part is the O-ring, which ensures tightness.

This installation method is good because it does not require any special equipment. The second advantage is that the connection is detachable and, if necessary, the fitting can be replaced. If it fails or there is a need to change the pipeline configuration. And it's very convenient.

But there is also a drawback: from time to time, a leak occurs on the threads. It can be fixed simply by tightening it half a turn. But because of this, all connections must be accessible and cannot be bricked up. Also annoying is the need to check whether it leaked or not. Not everyone likes it.

This is what compression fittings look like

The range of fittings is wide: angles, tees, crosses, adapters (from one diameter to another). And all this with different angles, in different diameters.

Installation of metal-plastic pipes on compression fittings begins with removing the union nut and ferrule ring and checking for the presence of a rubber seal. After this, the assembly actually begins:

- The nut and ring are put on the pipe.

- The section is pulled onto the fitting until it stops. The stop is indicated by a special small protrusion-shoulder.

- The ring is also stretched until it stops on the fitting.

Before tightening the nut - The union nut is tightened. First, by hand, the connection of the metal-plastic tubes is tightened using two keys. One holds the fitting body, the second turns the union nut.

That's all, the installation process of the compression (screw, threaded) fitting is completed. There is only one caveat: if you fill the system with antifreeze, change the gaskets immediately. The ones that come with the kit will leak with anti-freeze very quickly. Use paronite or teflon ones. Only they can ensure tightness. In general, for systems with antifreeze it is better to use press fittings. They definitely don't leak (if crimped correctly).

Possibilities of modern press jaws

In the field of installation of heating systems, polymer pipelines made of cross-linked polyethylene PEX, polypropylene PP with additional shells made of aluminum Al (fiberglass in PP) have long replaced steel pipes from use in this area.

However, metal has returned to heating systems in a different form and currently thin-walled pipes made of galvanized steel, stainless steel and copper are replacing plastic in the European market due to a number of significant advantages.

First of all, metal pipelines are environmentally friendly, are not subject to significant linear expansion, are oxygen-tight and have a significant service life, and thanks to the latest technologies they are easy to install.

To join them, no welding or threading is required; press pliers with special attachments are sufficient.

In the domestic market for installation services, the installation of thin-walled, corrosion-resistant pipelines can be afforded by customers with high incomes - the cost of such pipes is an order of magnitude higher than their polymer analogues.

Rice. 4 Types of press jaws

It is worth noting that modern tools for press fittings are produced in multifunctional models with replaceable crimping jaws or heads designed to work with various types of pipe materials. Standard pliers may include standardized attachments with different profile sections of replaceable press jaws, the letter designations of which are deciphered as follows:

- TN - crimp for pipes made of PEX-Al-PEX metal plastic with typical outer diameters of 16, 20, 26 (25) and 32 mm.

- U – profile for working with PEX-Al-PEX metal plastic; some users use a nozzle for crimping copper pipelines if the kit does not include special V profile jaws. Designed for crimping pipes with a circumference of 16, 20, 25, 32 mm.

- V – nozzle for crimping European-made copper and stainless steel pipes of sizes 15, 18, 22 and 28 mm.

- M – profile for crimping copper and stainless steel tubes made in China, South Korea and Europe with a circumference of 12, 15, 18, 22 and 28 mm.

- VUS is a crimp for pressing pipes produced in the USA and Canada in sizes 1/2, 3/4 and 1 inch.

- VAU is a profile for Australian-made copper and stainless steel pipes with diameters of 20 and 25 mm.

Above were the types and sizes of replacement jaws for modern high-quality hand and hydraulic tools.

In almost all electric and electro-hydraulic professional models, the maximum pressing threshold is a pipe diameter of 108 mm.

Rice. 5 Appearance of press jaws for hydraulic pliers

Installation of crimp (press or push) fittings on MP pipes

Installation of metal-plastic pipes using compression fittings requires special pliers. There are manual ones and there are electric ones. Any are equipped with a set of linings for different diameters. Manual ones, of course, are cheaper. You don’t have to buy this equipment—you’ll only need it once. It is much more profitable to rent.

Press fitting for MP pipes

The press fitting consists of two parts - the body itself and the compression sleeve. Before connecting metal-plastic pipes, the cut is prepared. It is the same as when using compression fittings, but the chamfer is removed only from the inside. The following is the procedure:

- A sleeve is placed on the pipe.

- A gasket is installed on the fitting to prevent electrochemical corrosion.

- The tube is put on the fitting until it stops. There is a hole on the fitting body in which the edge of the pipe should be visible.

- Take pliers in which suitable pads (of the required diameter) are installed. The pliers are installed close to the edge of the fitting, connecting the handles of the press together and crimping the part. As a result, two concave stripes should be clearly visible on the sleeve. Their depth should be the same. After crimping, the fittings can rotate around the pipe.

That's all, the installation of metal-plastic pipes using a press fitting is completed. Such a joint can withstand pressures of up to 10 atm, which is sufficient for most systems. Not suitable only for heating systems of houses with several storeys. more than 16. Their system pressure may be higher.

Advantages

The popularity that compression fittings have gained is largely determined by their technical characteristics:

- Installation does not require the use of complex welding equipment or qualified welders.

- You can connect sections of the pipeline or plug a dead-end branch with your own hands, using new connecting parts made from polymers.

- No special skills are required to install compression press fittings.

- The use of compression fittings made it possible to reduce the labor intensity of installation of the entire pipeline system and the time spent on these operations.

- Compression press fittings made it possible to install combined networks using metal-plastic, steel, polypropylene, plastic and pipes made of other materials.

- Compression fittings increase the maintainability of systems. They allow the connection to be quickly disassembled for maintenance or relocation to another location.

How to bend a metal-plastic pipe

Often when installing metal-plastic pipes, it becomes necessary to bend the pipe. This can be done by hand or using a spring. It’s easier and faster to work with a spring, but you have to buy one (it’s inexpensive). The spring is inserted inside the pipe and bent in the required direction. The pipe follows the bend, the spring is removed. It is easy to bend metal-plastic pipes with a spring - no great effort is required, the actions are easily controlled, and it is possible to correct the result.

What’s good about this method is that you won’t be able to squeeze the walls, which happens when you apply excessive force manually. It is also impossible to make a sharper bend (with a radius less than the minimum) and compress the walls at the bend, narrowing the flow section.

Spring for bending metal-plastic pipes

You need to bend MP pipes by hand gradually. Take it with your hands on both sides of the bend (at the same distance from the center of the future arc), with your thumbs supporting the pipe from below. In this position, begin to lower the edges down, while at the same time pressing upward with your thumbs.

Manual bending of metal-plastic pipes

With this method, sometimes the pipe loses its geometry due to excessive efforts. This negatively affects its throughput. Such areas cannot be installed in water supply or heating. To avoid such situations, the bend area is heated. This can only be done with a hair dryer. Open fire must not be used. Heated plastic is easy to bend. At the same time, it does not compress (the main thing is not to overdo it).

Methods for bending MP pipes

Another way to avoid deformation is to pour sand inside. It will not allow the walls to shrink.

Safety precautions when working with the tool

To use press tongs at home, you do not need specific knowledge or extensive work experience. You just need to carefully study the operating instructions and strictly follow everything that is written there.

Do not use the tool in rooms with high humidity. Dampness has a bad effect on metal and leads to jamming and incorrect operation of tools.

It is advisable to carry out the pressing process in comfortable, practical clothes, and protect your hands with thick construction gloves. To avoid injury and damage, do not allow parts of clothing or limbs to get into the working mechanism. Following these simple rules will help you perform crimping carefully, without damaging either yourself or the tool.

How to attach to walls

When the pipeline is laid open, it must be fixed to the walls in some way. Usually special plastic clips are used for this. They are single - for laying one pipeline thread. Typically used for plumbing installations. There are dual ones - most often they are installed for heating - supply and return in two-pipe systems run in parallel.

Clips for mounting metal-plastic pipes on the wall

These clips are installed every meter (as often as possible). A hole is drilled in the wall for each, and a dowel of the required type is inserted (selected depending on the type of material from which the walls are made). A large load is not expected, but plumbing and heating look much more attractive if everything is laid out evenly, as if on a ruler.

What is cross-linked polyethylene

This product is obtained by special processing (cross-linking) of polyethylene raw materials. As a result of the technological process, cross-linked polyethylene is formed, denoted by the abbreviation PEX. Compared to primary raw materials, it has improved characteristics, becoming more flexible, durable and heat-resistant.

Today, by cross-linking polyethylene, four types of cross-linked polyethylene are obtained: PEX-a, PEX-b, PEX-c, PEX-d. They differ in their operational properties:

- The most heat-resistant of them is PEX-a. It can withstand a maximum temperature of +90 ºC. At the same time, the polymer has high strength and flexibility.

- PEX-b is a common type of PEX polyethylene pipe. It can be multilayer, unlike PEX, and is characterized by wear resistance. However, it cannot be welded.

- A distinctive feature of PEX-c is its high environmental friendliness, which is why branches from it are widely used in the pharmaceutical and food industries. Its heat resistance for heating systems is insufficient - at ambient temperatures above +70 ºC it is not recommended to use Pex pipes.

- PEX-d are in low demand and difficult to manufacture.

You can determine whether what you have in front of you is cross-linked polyethylene yourself. You need to place a piece of the product in the oven and heat it to 180 degrees. If it has lost its shape or melted, this means it is a fake.

Any cross-linked polyethylene is characterized by a temperature memory effect, that is, when heated, it returns to its original shape after deformation.

Non-standard connections: with metal pipes, transition to a different diameter

When replacing plumbing or heating, it is often necessary to combine metal and metal-plastic. Most often this happens at the outlet from the riser. In this case, the metal pipe is cut at a certain distance - 3-5 cm, and a thread is cut on it. Next, a fitting with a union nut (collet) or internal thread is screwed onto the thread. Further installation of metal-plastic pipes proceeds according to conventional technology.

Some types of fittings that can be used when switching from metal to metal-plastic

The fitting is selected according to the diameter of the metal pipe, and the thread on the adapter must be internal - the external thread is cut on the pipe. This connection requires sealing. Wrap with flax and coat with packaging paste or simply use fum tape.

The connection of two pipes of different diameters occurs in exactly the same way. All you need is an appropriate adapter fitting with nuts/nipples of the appropriate diameter.

Why cross-linked polyethylene is not welded

The main problem for any pipeline is the connection technology. Therefore, the disadvantages of PEX bends include their inability to be welded, in contrast to their competitors - polypropylene pipes.

Intermolecular modification in the form of a cross-linking process led to the loss of thermoelasticity, which is characteristic of conventional polyethylene. PEX cannot form a continuous bond on its own.

At welding temperature it stops melting and simply becomes elastomeric. Thus, having received increased heat resistance, cross-linked polyethylene lost its ability to be welded.

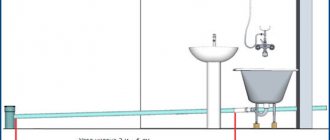

Example of water supply system layout

First, we draw a water supply layout plan. This can be done on a piece of paper, marking the necessary fittings. Please note that installation of taps requires installation of a fitting with a thread at the end. Taps are needed on taps to household appliances and plumbing fixtures, to heating radiators. This makes it possible to turn off devices without shutting down the entire system. The type of thread and its size are selected depending on the type of tap used.

An example of a water supply system using metal-plastic pipes

Also, transition fittings are needed before and after the meter (water or heating depends on the type of system). Having drawn a detailed plan, put down dimensions on all areas. Using this drawing, you calculate how much and what you need. Fittings can be purchased strictly according to the list, and it is advisable to take pipes with some reserve. Firstly, you could make a mistake when measuring, and secondly, in the absence of experience, you can spoil some piece - cut off less than required or crimp incorrectly, etc.

Agree on the possibility of an exchange

When purchasing everything you need, agree with the seller that you can exchange/return some fittings if necessary. Even professionals often make mistakes with them, and even more so those who decide to do the wiring of a plumbing or heating system from metal-plastic with their own hands. No one will take the rest of the pipe back from you, but fittings will easily be taken back. But to be sure, keep the receipt.

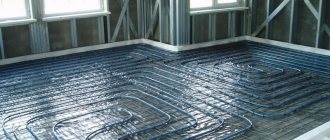

Sometimes it is more convenient to use collectors. They allow you to connect several consumers in parallel. There are collectors for plumbing and for heating (when installing heated floors)

When and how to start work

When you get home, lay out the fittings and proceed: installation of metal-plastic pipes in the summer can be done immediately, in the winter you need to wait some time (12 hours) until all the elements warm up to room temperature. It is advisable to cut one piece of pipe of the required length at a time. It's a little longer, but you definitely won't get confused. Further actions depending on the selected type of fittings.

Heating installation with metal-plastic pipes is done only with press fittings

After completing the installation of metal-plastic pipes, the pipeline is checked. If it is a water supply, just open the tap at the inlet. This must be done gradually and smoothly. The system will immediately begin to fill with water. If nothing leaks anywhere, you did everything right. If any connections are leaking, they must either be redone if press fittings were used, or tightened if the assembly was based on crimp connectors.

If a heating system was assembled from metal-plastic pipes, before starting it must be pressurized - tested with high pressure by pumping cold water into the system. If the test was successful, you can do a test run of the heating.

Recommendations for selection

When choosing press fittings for working with metal-plastic and deciding which one is good and which one is not of very high quality, you can adhere to the following recommendations.

- Since the body of a high-quality press fitting is made primarily from brass, which is a fairly heavy metal, you should evaluate the weight of the selected products: they should not be too light.

- The body parts of press fittings must have markings, which, if such products are of high quality, should be clearly legible.

- The appearance of the sleeve is another parameter that you should pay attention to when choosing a press fitting. In low-quality products, the sleeve may be made of thin metal and will look different from the entire fitting. It will not be possible to obtain a reliable connection if the press fitting is equipped with such a sleeve, since it will not be evenly pressed around the surface of the metal-plastic pipes being connected.

Thus, in order for the press fitting to efficiently compress metal-plastic pipes, the choice of such a product should be approached responsibly and competently.

To control the correctness of crimping, there are special templates, the use of which significantly reduces the likelihood of leaks in fitting connections.